Get Real-Time Insights Into Your Supply Chain Performance

TRUSTED BY 30+ GLOBAL FORTUNE 500 COMPANIES

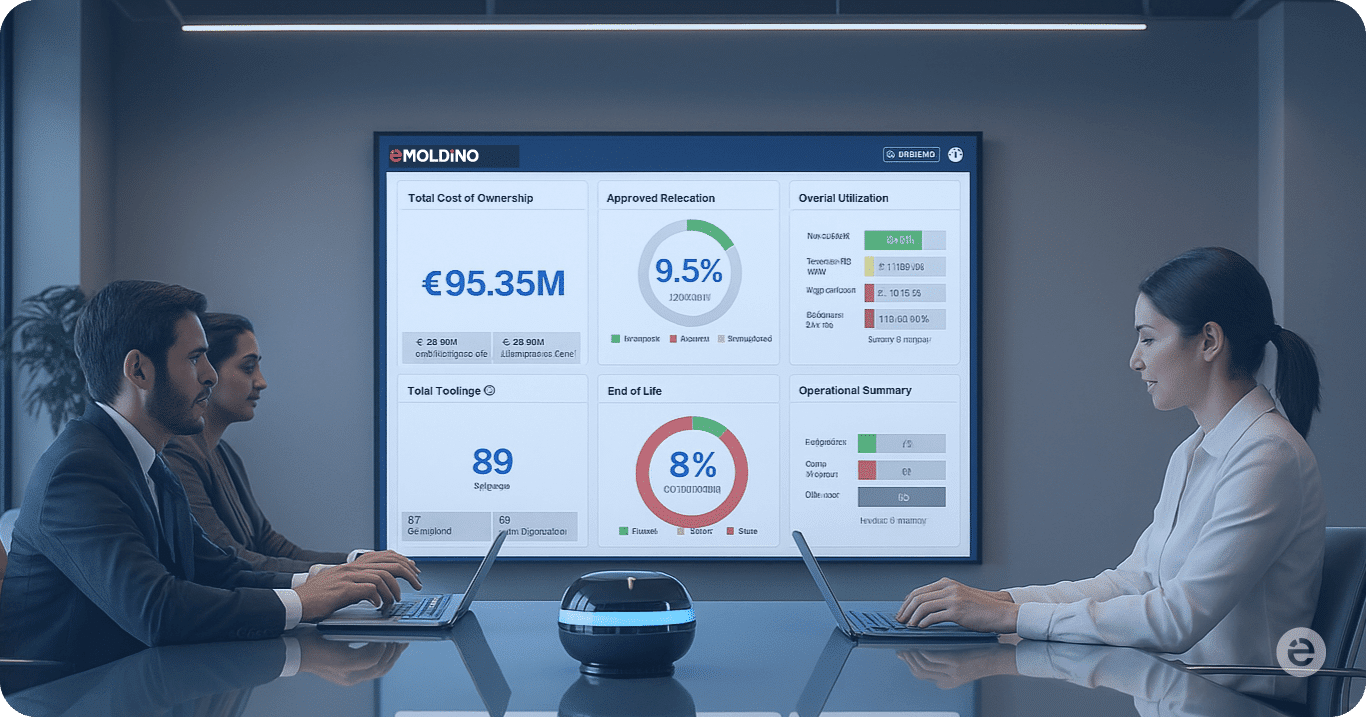

OUR PRODUCT AND SOLUTION

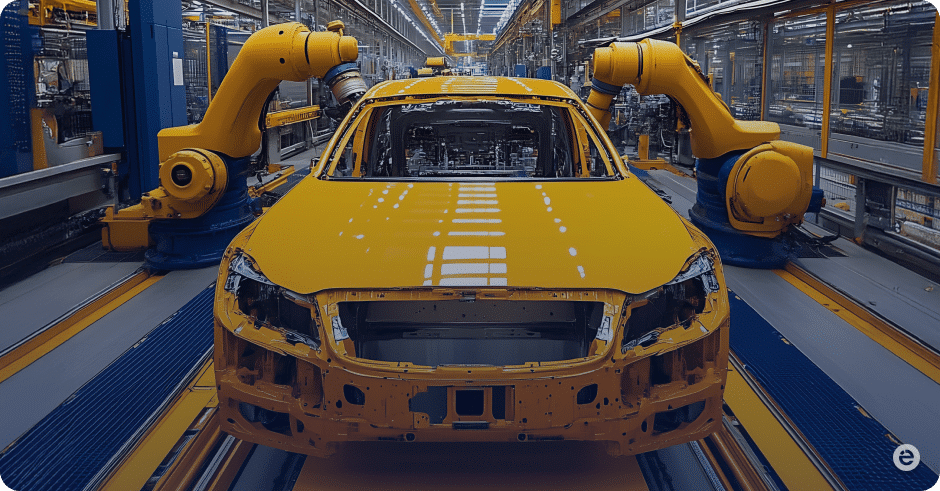

Outsourced Manufacturing Analytics Meets Supply Chain Optimization

IoT Sensor

Capture all your important outsourced manufacturing data in real-time through our proprietary plug-and-play IoT sensors.

Solution

Optimize your outsourced manufacturing and supplier operations by leveraging data-driven reports and predictive analytics.

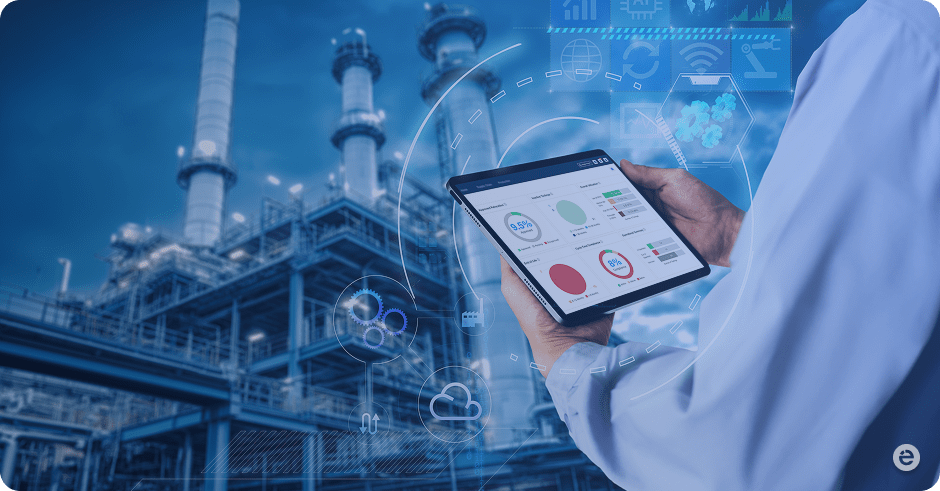

OUR NEW AI FEATURES

eMoldino’s AI solution is designed to deliver actionable insights that eliminate inefficiencies and mitigate risks in asset management and parts production.

Leveraging proprietary real-time data collected directly from the tooling level, our AI engine identifies patterns within accumulated data to generate highly accurate predictions.

Agentic AI Capabilities

- Tooling Health

- Capacity Planning

- Production Throughput

- Anomaly Detection

- Scrap Intelligence

AI Application

- Tooling Lifecycle

- Operational Efficiency

- Reduced Scrap Rate

- Integration with existing SCM solutions

WHY CHOOSE US

Why eMoldino?

Capacity Planning

Determine your suppliers’ actual capacity and receive insight into optimization potential

Tooling Audit

Look into your tooling’s whereabouts, condition, and operation in real-time

Plug-and-play installation

Easily install our wireless sensors within minutes and instantly see your system running

Life-cycle management

Instantly determine your tooling’s remaining lifespan and concisely follow up on any maintenance activity

Global Support

Rely on our trusted staff to support you worldwide and provide on-site trainings for all stakeholders

Process Change Analysis

Detect abnormal process deviations to preemptively determine which parts could be of lesser quality

Supplier Management

Streamline communication and collaboration with your suppliers for a more efficient and effective relationship

Collaborative Platform

Have all relevant parties involved on one collaborative platform, enhancing your organization’s digital thread

Explore Our Latest Posts