了解的公司 预测性维护 根据 2021 年轴承点调查,设备停机时间可减少 18%。这种现代化的方法彻底改变了以往的被动维护模式,即团队等待设备出现故障后再进行修复。

预测性维护利用物联网、人工智能、ML 和云技术来观察系统性能,并在故障发生前发现问题。这些数字说明了一个令人信服的故事--企业的维护和服务成本下降了 17%,而预测性维护项目的收入增长了 10%。您的机器寿命更长,问题诊断能力更强,服务质量提高,您甚至可以创造新的盈利方式。

让我们一起探索专为工具制造商设计的预测性维护流程。您将学习到不同的技术,看到现实生活中的应用,并获得清晰的操作步骤。无论是新手还是经验丰富的专业人员,这篇文章都能帮助他们找到实现更智能、更经济的维护的最快途径。

工具制造商在没有预测性维护的情况下面临的挑战

制造部门的工具制造商在运营和财务方面面临的最大挑战是,他们只能依靠 被动维护 方法。这些数字说明了一个严峻的问题:工业制造商损失了大约 1.5 亿美元。 每年 500 亿美元 意外停机造成的损失。一个小时的停机时间可能给公司造成的损失超过 100,000 美元.

金钱的损失远不止是修修补补那么简单:

工具在失效和接近报废期时,因零件不符合规格而损坏和产生废料

如果没有适当的维护,设备会加速老化,造成原始资本投资的浪费

紧急维修费用 5-7 倍 比计划的预防性工作

反应性维护会造成生产瓶颈。制造商损失 800 小时 每年的停机时间一般为 4 小时.维护团队浪费 20% 他们的时间都花在了去正确的工厂地点解决问题上。

备件管理是另一个令人头疼的问题。维护团队经常找不到关键零部件,即使仓库已经满溢。一家发电公司发现,类似的组件在不同的地点有不同的名称,这导致了重复列表。

工人短缺使这些问题更加严重。由于经验丰富的员工退休,合格的工人变得稀缺,公司很难有效地管理其设备。寻找和留住优秀员工变得更加困难。

维护不善会扰乱整个组织。延迟交货会影响客户满意度。设备运行不正常会导致质量问题。维护不当的工具可能会损坏或发生故障,给操作人员带来风险。

工具制造商现在必须做出一个关键决定:是坚持采用价格昂贵的被动式方法,还是转而采用能及早发现问题的预测性维护策略。

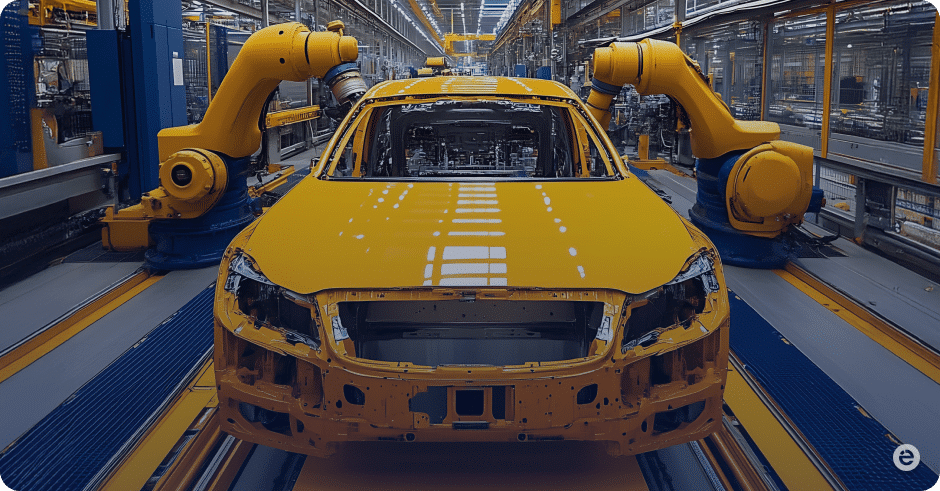

工具制造商的预测性维护技术

正确的监测技术可使预测性维护在工具制造操作中发挥良好作用。传感器通过状态监测收集重要的性能数据,在潜在故障发生之前就能发现。

振动分析可帮助工具制造商检测旋转机械的机械失衡和校准问题。研究表明,振动传感器可以发现异常模式,从而发出即将发生故障的警告,让维护团队在问题变得昂贵之前及时介入。热成像技术可以发现过热的部件,声学监测技术可以捕捉到需要润滑的轴承发出的细微声音。

先进的分析系统可将原始传感器测量结果转化为适用信息。XG Boost Classifier 和长短时记忆 (LSTM) 网络等人工智能模型在预测工具故障时显示出更高的准确性。这些系统可根据基线数据分析运行状况,即使是微小的效率下降也能迅速发现。

您可以通过以下方式设置系统

在关键设备上安装物联网传感器,以监控温度、振动和压力

将传感器连接到集中式 CMMS 或云平台进行数据处理

使用机器学习算法识别模式和异常情况

创建触发维护干预的警报机制

现代系统利用云计算和边缘处理技术,实现无延迟的实时监控。数字孪生技术通过创建物理工具的虚拟副本来改进预测。维护团队可以在做出决策前测试不同的方案。

这种明智的方法带来了实实在在的效果。与使用反应性维护的制造商相比,使用预测性维护的制造商非计划停机时间减少 52.7%,缺陷减少 78.5%。使用人工智能驱动的预测性维护的公司,通过停止故障和减少废品,每台机器每月可节省数千美元。

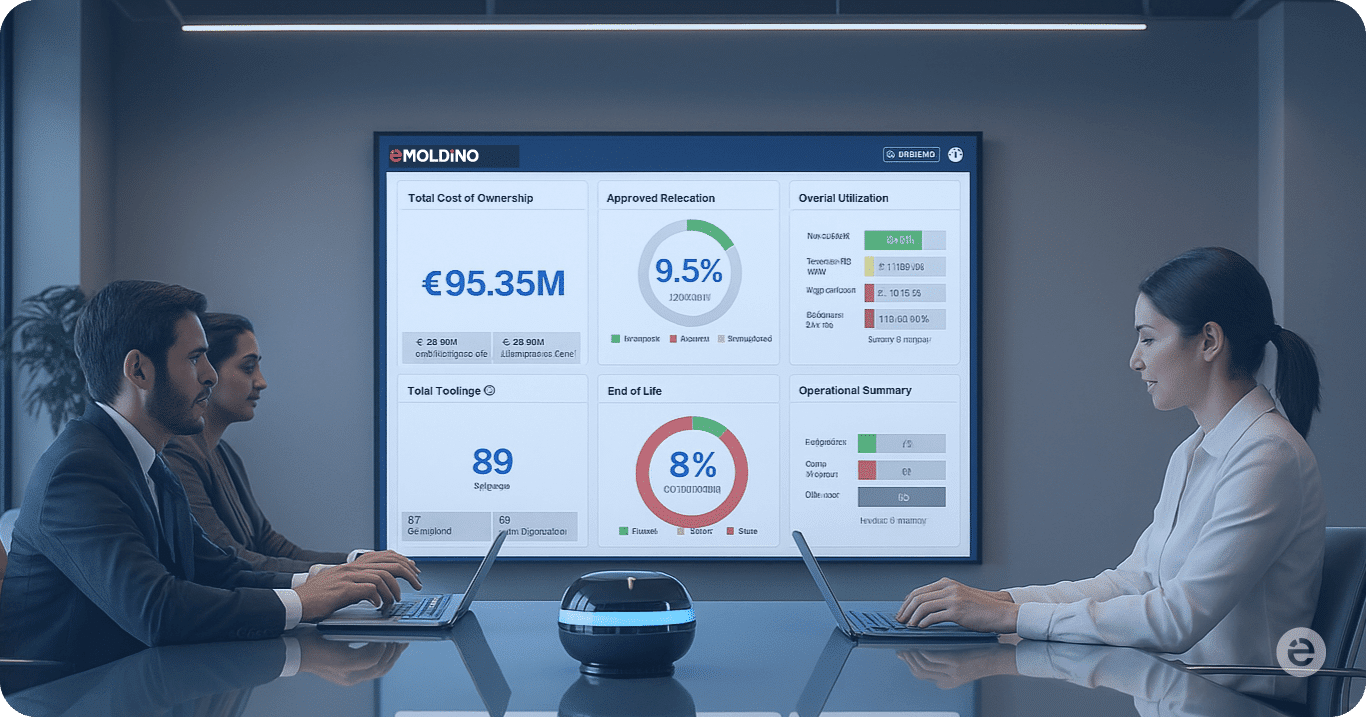

与 eMoldino 专家交流 了解适合您的工具制造操作需求的解决方案。

关于作者

eMoldino

eMoldino

eMoldino 致力于数字化、简化和改造您的制造和供应链运营。我们帮助全球制造商推动企业创新,同时保持协作和可持续发展的核心价值。 请与我们联系,了解更多信息 →

您喜欢阅读这篇文章吗?

0 /5.计票: 0

浏览我们的最新文章