You might be surprised that 21.8% of global supply chain executives struggle to monitor their outsourced suppliers. Supply chain leaders have poured money into new technologies, yet 69% of them aren’t seeing the results they expected.

Your entire operation could suffer from the challenges of managing outsourced suppliers. Supply chain teams leave more than 80% of their data unanalyzed, which leads to missed opportunities and waste. Poor visibility of partner networks and fragmented communication systems create most problems with supplier management.

The control tower market tells an interesting story. Its value will jump from $2.58 billion in 2018 to $17.24 billion by 2027. Supply chain control towers bring together people, processes, data, and technology. These towers help companies see clearer and make better decisions, especially when working with external partners.

Let us show you smart ways to keep track of your outsourced suppliers using control tower features. We’ll cover everything from continuous intelligence to shared response tools. These insights will help change your supplier management and give your supply chain the visibility it needs.

What Is a Supply Chain Control Tower?

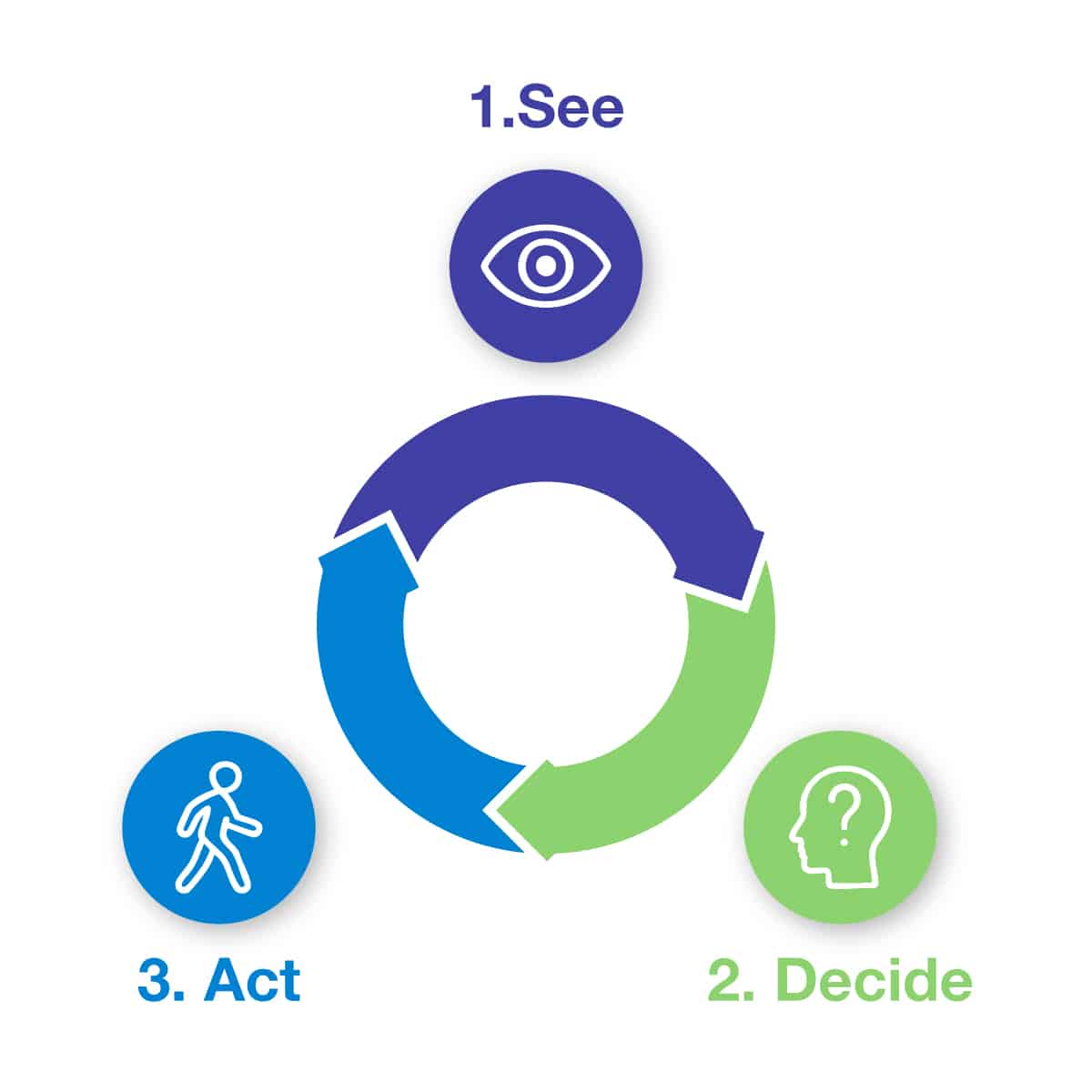

A Supply Chain Control Tower works as the nerve center of modern supply chains, especially when you have businesses managing complex networks of outsourced suppliers. These towers are more than simple dashboards – they’re detailed cloud-based digital platforms that bring together people, processes, data, organization, and technology into one system [1].

The control tower acts as a central hub that gives you complete visibility and control of your supplier network. You can see beyond your internal operations and watch over external partners, which helps you keep an eye on outsourced suppliers like never before.

Think of it like an airport control tower coordinating flights – a supply chain control tower will give a smooth flow to every part of your supply chain from buying to delivery. This becomes crucial when managing outsourced suppliers who might otherwise work separately from your main systems.

Modern control towers stand out because of their tech foundation. These systems use advanced technologies including:

Artificial intelligence and machine learning to predict trends

Internet of Things (IoT) to collect live data

Cloud computing to share information smoothly

Advanced analytics to model scenarios and support decisions

Today’s control towers do more than show information – they help make smarter decisions. Gartner points out that “Supply chain technology leaders see control towers as extensively visual dashboards and, sometimes, fail to use them as analytics-driven, decision-support tools”. The real value comes from using data to see what’s happening now and analyze it deeply.

These towers collect data from many sources – weather updates, traffic patterns, remote sensors, and past performance. This creates a complete picture that lets you manage global outsourced suppliers precisely. You can spot problems before they affect your operations.

Control towers work as part of larger supply chain management systems. They take live operational data from your business network, including outsourced suppliers, to improve visibility and help make decisions that match your strategic goals.

The main questions a control tower answers are simple: Do customers get what they want when needed? Can you deliver within budget with the right inventory? Are you hitting targets while keeping quality high?

Companies struggling to manage outsourced suppliers find solutions in control towers. These systems break down information barriers and make previously separate operations transparent. Teams can now evaluate and handle supply chain events as one unit.

You get more than just visibility with these systems. They let you track supplier performance live, catch problems automatically, and work well across company boundaries. This changes outsourced supplier management from reactive to proactive oversight.

The control tower gives everyone real-time access to supply chain data. Supply chain professionals can now make faster, better decisions about supplier relationships across all areas.

The benefits are clear – control towers help predict disruptions, build stronger systems, handle exceptions, and react quickly to unexpected events. Organizations that depend heavily on outsourced suppliers see this as a transformation from old management methods to a more connected, evidence-based supplier strategy

Why Visibility Matters in Managing Outsourced Suppliers

Only 16.9% of logistics stakeholders say they have true end-to-end supply chain visibility into their outsourced supplier operations. The numbers tell a stark story – about 87% of supply chain executives now outsource much of their operations. This marks a huge jump from just 10-20% back in 2000.

Common problems with managing outsourced suppliers

Communication breakdowns rank high among outsourcing challenges. Teams working with external partners often face misunderstandings that cause delays and costly fixes. Language and cultural gaps make things worse, as external staff might just agree with clients instead of pushing back on unrealistic requests.

Quality control becomes a real challenge too. Organizations can’t directly oversee third-party providers, which makes quality monitoring tough. Without proper oversight, companies only spot quality issues after they’ve already hurt operations or customer satisfaction.

Data security raises red flags when sharing sensitive information with outsourced partners. Companies lose direct control over their data security and risk potential breaches. Extra costs also pop up throughout these partnerships, including:

Training new staff

Fixing miscommunications

Managing legal issues

Fixing preventable quality problems

The “out of sight, out of mind” attitude toward outsourcing can be dangerous. The COVID-19 pandemic showed just how big the gaps were between companies and their outsourced logistics providers. Even before the pandemic hit, an Ernst and Young survey showed supply chain executives ranked visibility as their top priority.

How lack of visibility leads to delays and cost overruns

Companies enter a “black hole” without proper visibility – they can’t track orders once placed. They miss out on real-time supply chain activities like order status, process timelines, paperwork, and possible issues. This lack of transparency causes operational problems that hurt the bottom line.

Take this example of an advertising agency working with a design firm on campaign visuals. Their contract didn’t specify revision turnaround times. The design firm took weeks for each revision, pushing the project three weeks past deadline. Project costs jumped 25% due to extra management time and rush fees needed to launch the campaign on time.

Poor vendor management hits budgets in two key ways:

Unclear communication about deliverables, timelines, and quality standards leads to surprise delays and costs

Manual expense tracking often misses costs that break budgets, like forgotten payments, surprise charges, and exceeded revision limits

Customer relationships take a hit too. Research shows 69% of consumers will likely shop elsewhere if their order arrives more than two days late. Without real-time updates, companies can’t spot order changes, stock shortages, or shipping problems before customers notice.

The Business Continuity Institute reports that 72% of suppliers who faced supply chain problems lacked the real-time visibility to fix issues quickly. All the same, 60% of businesses only find out about shipping damage after delivery – if at all.

This visibility problem affects the entire supply chain. In today’s complex system with multiple handoffs, 37% of companies still can’t track shipments properly, leaving them open to delays, damage, and theft. As Tive CEO Krenar Komoni puts it, “Knowing where a shipment is doesn’t mean much if you don’t know what’s happening to it”.

The Evolution of Control Towers

Supply chain control towers have come a long way since their start in the early 2000s. Initially created as simple monitoring tools with limited scope, these systems have grown into sophisticated command centers that can orchestrate complex networks of outsourced suppliers. This rise mirrors the changes in supply chain management. The old linear models have given way to intricate, interconnected ecosystems.

From siloed systems to integrated platforms

The first control towers worked as standalone systems with a narrow focus. These original solutions watched specific parts of operations like transportation, logistics, or warehousing. Companies installed them as on-premise software with limited capabilities. The digital world had various specialized towers:

Logistics control towers

Operational control towers

Transportation control towers

Analytical control towers

Inventory control towers

Each type came with major drawbacks. To cite an instance, analytical control towers offered analysis but gave no guidance to fix problems. Transportation control towers tracked shipping data and nothing more. The biggest issue was that these early systems only showed immediate trading partners. This created blind spots in managing outsourced suppliers down the chain.

This split system made it hard to coordinate work. A Gartner survey showed that an average disruption needed at least 34 manual system updates across 6 different platforms. This count only included direct system actions, not communication tasks. MIT research found that one disruption created 25 emails needing input from 8 different roles.

Things changed as supply chains became more complex and global. Companies found it harder to organize and solve problems using disconnected old systems. This problem grew worse when managing outsourced suppliers. Traditional “war rooms” depended on Excel spreadsheets, emails, and phone calls to handle issues that siloed control towers couldn’t fix automatically.

Today’s integrated platforms mark a basic change from these split approaches. Modern control towers connect previously isolated systems through unified platforms. This connection allows steady data flow, better reporting, and detailed operational visibility. Users can now check order status, move inventory between distribution centers, watch yard operations, and track shipments in one system.

“Control Tower capabilities as a concept, the result of people, process and organization facilitated by appropriately combined technology elements including Data-driven E2E supply chain insights and E2E decision making enabled by Visualization, Diagnostics, Predictive, Simulation, Responsive Collaboration, Learning and Automation”

– Gartner

Role of cloud, AI, and IoT in modern control towers

Three key technologies have revolutionized control towers. First and foremost, cloud computing has changed how control towers work. An IDC survey found that 67% of organizations named cloud as their top technology to affect supply chains—far ahead of other innovations. Cloud platforms have broken down old data silos. Teams can now access critical information and work together across continents.

Cloud’s computing power and its ability to process huge amounts of data—combined with artificial intelligence and machine learning—have redefined control towers’ capabilities. AI-enabled control towers now do more than show information. They can:

Predict delays before they happen

Find inefficiencies in supplier networks

Fix problems automatically

Calculate inaction costs and suggest best responses

The Internet of Things acts as modern control towers’ sensors. IoT devices capture live data throughout the supply chain. Temperature sensors check pharmaceutical cold chains, GPS trackers follow high-value shipments, and equipment sensors predict repairs. This constant data collection gives unprecedented insight into outsourced supplier operations.

The financial impact of this progress is huge. The global control tower market, worth USD 2.58 billion in 2018, could reach USD 17.24 billion by 2027. In fact, experts expect the market to grow at 21.3% yearly from 2023 to 2030. This growth comes mainly from the need to digitalize supply chain processes.

Ultimately, modern supply chain control towers provide complete visibility across all operations, including outsourced suppliers. Unlike older systems that needed more people to fix issues, today’s control towers use AI to move from basic reporting to predictive insights and automatic decisions. This advancement helps organizations change how they manage outsourced suppliers. They now use analytical insights instead of just solving problems as they come up.

Key Benefits of Implementing a Control Tower

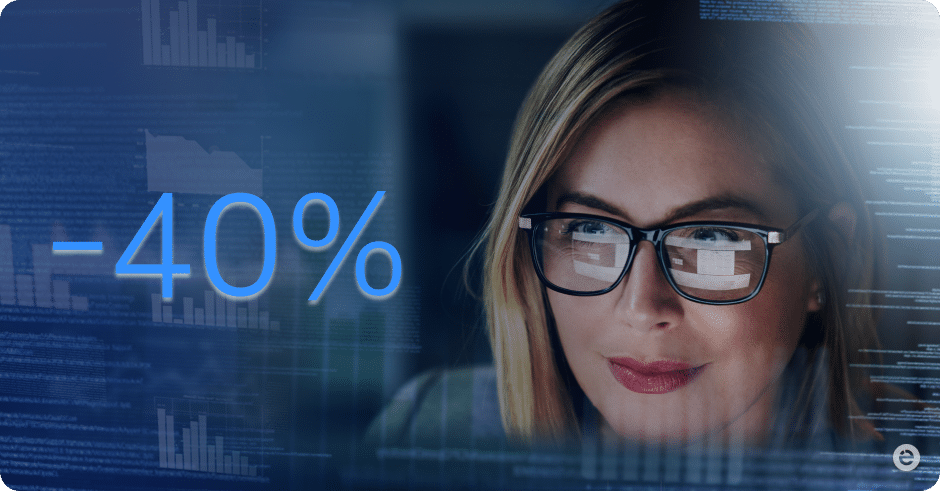

Supply chain control towers help organizations earn more money when they work with outside suppliers. Companies using these systems have seen their revenue grow by 1% increase in revenues. They cut logistics costs by 3-5% and boost worker efficiency by 10-20%. These numbers show just a glimpse of what control towers can do.

Real-time decision-making

Quick, informed decisions reshape how businesses handle their outside suppliers. Old methods relied on past data that led to slow responses and lost chances. Control towers give instant insights that turn reactive management into active oversight.

Today’s control towers process data from many sources right away. This helps supply chain managers to:

Spot problems before they turn into big issues

Change delivery routes quickly as needed

Make fewer guesses when deciding what to do

This helps a lot with outside suppliers because it removes delays in communication that often happen with third parties. Control towers work with AI and machine learning to use predictive analytics. They tell you what will happen instead of just showing what already happened.

Studies show that only 2 out of 10 companies know 75%-100% of what happens in their supply chain as it happens. Companies that use control towers gain a big edge over their competition because they can see everything clearly.

Improved supplier collaboration

Control towers make it easy to work together across company lines. These systems bring sourcing and procurement data to one place, so many companies can work together better.

Supply chain control towers connect systems, people, and suppliers in one shared space. Hundreds of suppliers and partners can work as one team to get better results. This works well because:

Everyone shares information quickly across company lines

Each company sees data beyond their own work

Teams fix problems together before they get worse

The system replaces error-filled spreadsheets that quickly become outdated. It cuts down work by gathering supplier data automatically and creates clear accountability.

Inventory optimization across partners

Managing inventory with multiple suppliers used to be hard. Control towers solve this by showing inventory across the whole network. Companies now have what they need, exactly where and when they need it.

The system makes things better through:

One view of inventory for all supply chain partners

Live tracking of stock levels from connected data

Smart systems that order more stock when needed

The money saved is substantial. Control towers track every dollar spent to help with budgets and profits. Companies usually see stock move faster, keep less inventory, run out less often, and face fewer shortages.

Inventory optimization works even better across multiple companies. Unlike old methods that improved one stage at a time, control towers make everything work together. They optimize inventory at every level—from suppliers of raw materials to factories and warehouses.

Smart Ways to Monitor Outsourced Suppliers

Supply chain leaders need more than basic check-ins and reports to monitor outsourced suppliers. Sophisticated analytical tools now help them turn massive data sets into practical insights. These tools let organizations tackle common supplier management problems with evidence-based strategies.

Use of predictive analytics for supplier performance

Predictive analytics has changed the game in supply chain management, especially when you have outsourced suppliers to monitor. This method uses historical data, statistical methods, and machine learning algorithms to spot problems before they disrupt operations. Companies can now take preventive steps by anticipating challenges instead of scrambling to fix issues after they happen.

Predictive analytics brings several advantages to supplier management:

Early risk identification: AI can spot potential supply chain disruptions by analyzing patterns from big data sets before they affect your business

Performance trend analysis: Machine learning algorithms keep track of supplier performance data to show which partners meet standards and which fall behind

Supplier risk scoring: Risk assessments come from measurable factors like delivery times, quality issues, and financial stability

Manufacturing companies, to name just one example, can use predictive models to spot high-risk suppliers based on past performance metrics. This helps them vary their supplier base before problems arise. Procurement teams can then pick reliable suppliers, set the right inventory levels, and plan for disruptions.

Setting up predictive analytics comes with its own set of challenges. Poor data quality stands out as the biggest problem since these models need complete historical information, which often sits scattered across different systems. Companies also need proper infrastructure and talent. Data scientists, engineers, and industry experts must work together to develop these models.

Setting up automated alerts and exception handling

Automated alert systems work like an early warning network for supplier issues. These systems track performance metrics and send notifications when numbers cross preset limits.

Here’s how to set up effective supplier alerts:

Define event triggers that start alerts based on specific supplier actions or threshold violations

Set alert parameters and levels based on impact, time sensitivity, and likelihood

Configure notification templates with clear subjects and relevant content

Manage alert recipients by creating appropriate groups and determining alert frequency

Alert systems can watch various supplier events. Notifications can track changes in supplier performance scores, payment behavior, or environmental compliance. The system lets you set different alert conditions like “value rises above,” “value drops below,” or percentage-based changes.

Exception handling works alongside alert systems to give a clear path for fixing identified issues. Supply chain planners can quickly talk to suppliers about changes, which prevents material shortages, late deliveries, and excess inventory. Companies that use structured, workflow-driven processes for handling exceptions have cut their resolution time by up to 65%.

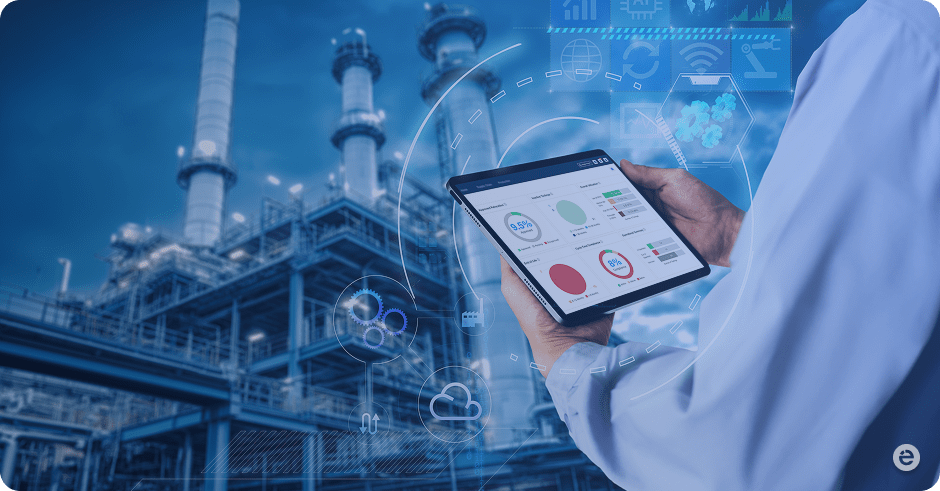

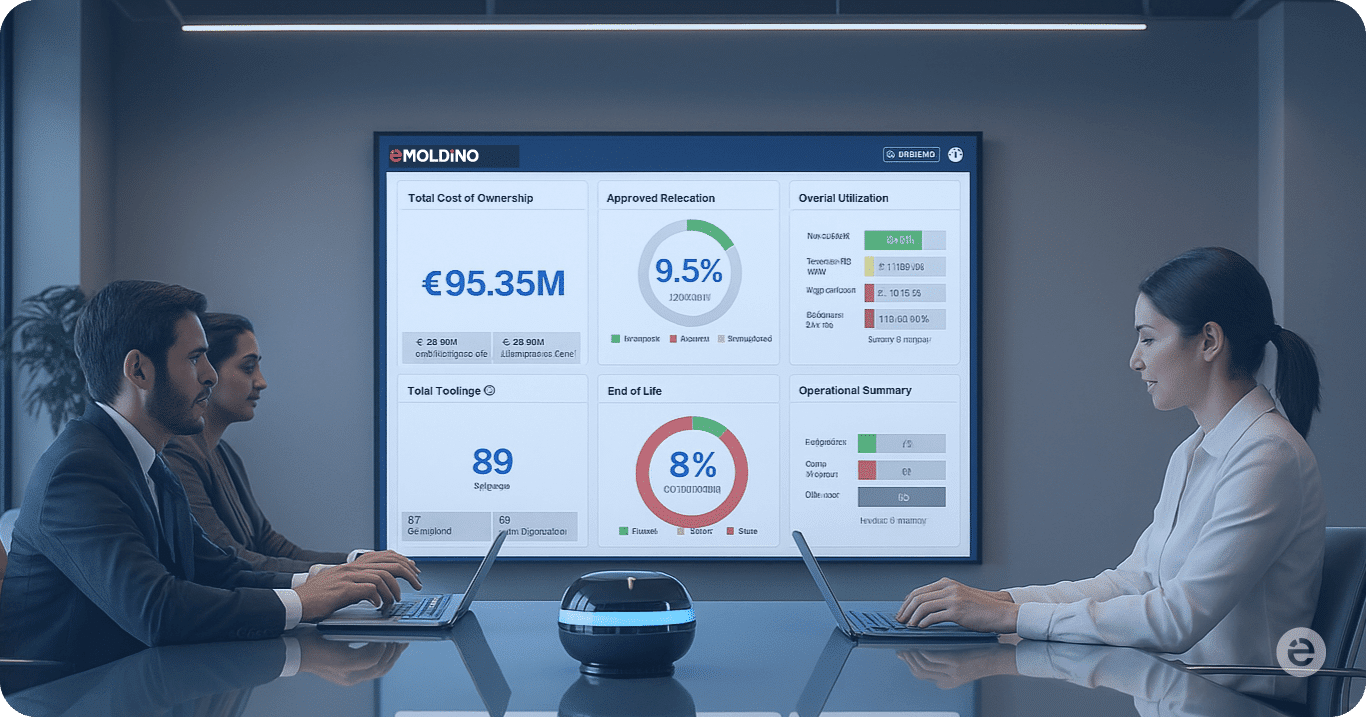

Tracking supplier KPIs in real-time dashboards

Visual dashboards help make quick decisions by turning complex supplier data into easy-to-understand charts and graphs. These tools combine information from all supply chain stages.

Good dashboards should track these essential supplier performance KPIs:

Delivery times and schedule compliance

Product quality metrics and defect rates

Response times to questions or issues

Financial stability indicators

Compliance with contract terms

Up-to-the-minute data analysis lets supply chain managers spot problems early. Teams can customize their view to track specific metrics like inventory turnover or lead times.

Modern dashboard solutions give different team members access to information that matches their job needs. Procurement teams, logistics managers, and executives each get their own tailored view of supplier performance data.

These dashboards will give a complete picture of operations by bringing live data into one accessible interface. Procurement teams can build better supplier relationships with clear visibility into performance history and communication records.

Steps to Implement a Supply Chain Control Tower

A supply chain control tower needs careful planning and a smart strategy, especially when you manage complex networks of outsourced suppliers. According to Gartner’s definition, a control tower brings together people, process, data, organization, and technology to boost visibility and decision-making.

Define business goals and scope

Your control tower needs clear strategic objectives. These objectives should tackle specific challenges in managing outsourced suppliers and line up with your company’s broader goals. You need to assess your supply chain to make sure current processes match your strategy. This phase includes:

Spotting key challenges and company objectives that will set your priorities

Setting SMART (specific, measurable, achievable, relevant, time-bound) objectives

Deciding what operations the control tower will handle now and in the future

Looking at current capabilities to figure out what you need to scale

The best solutions match your strategic roadmap and naturally add more supply chain functions, rather than just focusing on cost.

Map data sources and integration points

The next step is to get into critical business operations and enterprise systems, both current and future. This mapping phase covers:

Spotting high-level data flow architecture and system interfaces

Creating data structures for relevant interfaces

Finding existing data and high-value use cases for the control tower

Cleaning data for current use cases instead of fixing all quality issues at once

External data from outsourced suppliers, carriers, and IoT devices help fill gaps in your dataset. This turns your available data into a valuable asset, letting your control tower provide actionable insights.

Choose the right technology stack

Building innovative capabilities starts with a reliable initial infrastructure for your control tower. Your technology selection should:

Focus on systems that offer up-to-the-minute data analysis

Work well with existing ERP and other platforms

Connect smoothly with internal and external systems

Look at cloud platforms that break down traditional data silos

Include AI and machine learning capabilities for predictive insights

Your technology stack should support complete visibility, especially into unexpected external events with outsourced suppliers. Quality data powers an effective control tower and shapes visibility levels and actionable insights for supplier relationships.

Technology Capabilities You Need

Building an effective control tower demands specific technological capabilities that work together to provide detailed visibility into outsourced suppliers. These capabilities are the foundations of any future-proof supply chain control tower, according to Gartner.

Continuous intelligence and event monitoring

Continuous intelligence serves as the life-blood of modern control towers and processes data immediately to enable swift decision-making. This capability combines stream processing with business activity monitoring to analyze signals from your supply chain ecosystem continuously. Traditional reporting systems operate on historical data, while continuous intelligence platforms utilize artificial intelligence and automation to detect patterns, identify anomalies, and generate instant insights.

Smart control towers speed up analysis and reduce errors by eliminating spreadsheets and manual cross-silo analysis. They establish a trusted single source of truth for managing outsourced suppliers. This method turns available data into a valuable asset, helping your control tower deliver practical insights about supplier performance.

Scenario modeling and impact analysis

Scenario modeling capabilities help simulate different supply chain scenarios before implementing changes. The technology helps understand how disruptions affect both upstream and downstream operations. To cite an instance, see how control towers analyze and compare data using digital twins to predict deviations that affect shipments from outsourced suppliers.

Interactive heat maps and risk scores from impact analysis tools demonstrate the criticality of business at risk, based on supplier profiles. This capability helps assess suppliers’ criticality and detect vulnerabilities at the category level, protecting against operational risks.

Collaborative response tools

Collaborative response mechanisms connect stakeholders throughout your entire supply chain ecosystem. AI-powered resolution rooms and digital playbooks help teams respond quickly to unplanned events with outsourced suppliers.

Effective collaboration spaces help teams assemble, define goals, assign tasks, share information, and communicate outcomes. Breaking down silos and enabling immediate information exchange between all partners results in better supply chain planning.

Overcoming Common Implementation Challenges

Supply chain control tower implementation comes with several challenges that companies must tackle to maximize its benefits. Many organizations don’t realize how much time and work it takes to deploy these systems effectively when managing outsourced suppliers.

Breaking down functional silos

Siloed organizational structures remain one of the main challenges to control tower success. Poor communication and coordination between departments slow everything down and increase errors. These silos create a ripple effect that reaches customers through longer lead times and inaccurate orders.

Strong leadership and alignment from all stakeholders drive true end-to-end integration. Companies that succeed take these steps:

They build high-performing cross-functional teams with representatives from procurement, operations, finance, and other relevant departments

They set shared key performance indicators that reflect both procurement objectives and operational requirements

They hold regular collaboration sessions between procurement officers and facility managers

These methods help strategic sourcing decisions line up with operational needs and break down traditional barriers between purchasing and operations.

Ensuring data ownership and governance

Data ownership becomes critical when multiple business partners feed information into the control tower. Companies must decide who owns the data, who can access specific information, and who should assess the data.

Reliable and accurate data needs strong quality and governance policies. Companies should focus on cleaning data for their original use cases instead of fixing all quality issues at once. This approach helps transform available data into valuable assets for managing outsourced suppliers.

Training teams for new workflows

New skills and workflows come with control tower implementation. Teams often resist change, so companies must invest in detailed training programs.

The most successful implementations include:

Live and offline training for all users, including suppliers and business partners

“Train the trainer” sessions to strengthen key users within the organization

Organization-wide adoption through well-laid-out rollout plans

Companies that develop high-performing supply chain teams through training see better efficiency, adaptability, and employee satisfaction. This investment gives teams the skills they need to excel at managing outsourced suppliers in the control tower environment.

Conclusión

Supply chain control towers offer a new way to manage outsourced suppliers. They combine technology, people, and processes into one system that fills the visibility gaps in modern supply chains. This guide shows how these powerful platforms do more than just create dashboards – they become detailed command centers that give unprecedented oversight of external partners.

The numbers tell a compelling story – from 1% revenue growth to 20% better labor efficiency. These gains come when you implement the right steps: define clear business goals, map key data sources, and pick suitable technology. Your control tower needs continuous intelligence, scenario modeling tools, and ways to respond together to deliver the best results.

Companies that use this approach stop fighting fires and start managing suppliers proactively. The system spots potential problems early through predictive analytics. Automated alerts show issues that need attention, while immediate dashboards display vital performance metrics. This gives companies better control over their previously disconnected supplier networks.

Obstacles exist – breaking down department barriers, setting data rules, and training teams on efficient processes. Organizations that overcome these challenges build supply chains that stay strong during disruptions while working efficiently. Read the full article to learn more about changing your supplier management approach.

A control tower implementation is more than just a technology investment – it builds organizational strength. Better visibility, smarter decisions, and stronger supplier relationships make this investment worthwhile. The supply chain world changes faster each day, but one fact remains: companies with clear visibility into their outsourced supplier networks gain a powerful edge in today’s complex business world.

Sobre el autor

eMoldino

eMoldino

El objetivo de eMoldino es digitalizar, agilizar y transformar sus operaciones de fabricación y cadena de suministro. Ayudamos a los fabricantes globales que desean impulsar la innovación corporativa manteniendo los valores fundamentales de colaboración y sostenibilidad. Hable con nosotros para saber más →

¿Le ha gustado leer este artículo?

4 / 5. Recuento de votos: 1

Explore nuestras últimas publicaciones

Los OEM globales adoptan la tecnología de gestión de proveedores en tiempo real

Por qué los proveedores se benefician de la solución Smart Tooling de eMoldino

Protegido: Honeywell Boosts Tooling Efficiency with eMoldino’s IoT Innovations

Protegido: Eaton Saves Millions with eMoldino’s Tooling Digitalization Solution